问题一:

CG的垂直位置在哪里?它在发动机和机翼的交界处吗?对于一架在地面的空飞机,CG的垂直位置的高度是多少?

RESPONSE:

Vertical centers of gravity are not typically tracked in operation as it is difficult to measure them in the first place and then to track them over the life of the airplane. Airplane longitudinal CG is determined at a regular weighing based on the airplane being leveled longitudinally. Lateral CG can be determined at the same time but requires the airplane to be leveled laterally and that is not a requirement and usually isn’t done. To measure vertical CG, one needs to place the airplane weigh scales at different – and KNOWN – vertical locations, and the logistics to put the airplane into such a configuration are very involved such that no one does it. Operationally, knowing the lateral and vertical CG is basically informational and not otherwise useful for daily operations.

When Boeing does the initial aircraft design and certification analysis, we determine the CG in all 3 dimensions. But since the lateral and vertical CGs aren’t measured or tracked in operations, any limitations that might be affected by changes in the lateral and/or vertical CG are “translated” into something else. For lateral, that is usually to limit the weight difference between the left and right sides of the airplane. The true airplane CG isn’t at 0.0 left/right but it’s not far off from that, and by limiting the weight difference left/right, we ensure the operational airplane CG stays close to the analyzed value.

Vertical CG is not traditionally a driver of limitations as the design teams typically consider the range of possible vertical CGs for a given airplane configuration during the design stage. And since this range usually covers all vertical CGs that an operator could configure the airplane for, the operator wouldn’t see a vertical CG that wasn’t considered during the design phase.

The aircraft rotates about its 3-dimensional center of gravity during flight. That center of gravity moves depending on how the aircraft is loaded. So from a flight rotation perspective, the 3 axes cross at the aircraft center of gravity. But all of the weight and balance paperwork calculates the aircraft center of gravity relative to a different scale. The (x, y, z) = (0, 0, 0) point on that scale is typically forward of the nose (x), along the aircraft centerline (y), and about 200 inches below the main deck floor location (z).

If attachments are referred to and are not present, please access them by logging into the Boeing Communication System on MyBoeingFleet or contact your Boeing Field Service Representative.

Sincerely,

Ingrid M. Wakefield, Flight Operations Support

Ryan Vas, Manager

Customer Support

The Boeing Company

BCA Operations Centers 24 Hour Contact Numbers

787: +1 (206) 544-7787

All Other Models: +1 (206) 544-7500

Link to the Boeing Communication System: https://boeinginservice.my.site.com/a2F6g0000012z5AEAQ

(Note: MyBoeingFleet portal login is required to access link in the Boeing Communication System)

垂直重心在飞机的运行中通常不会被测量追踪,因为它的测量本身颇具挑战性,而且在整个飞机使用寿命中对其进行监控也极为困难。飞机纵轴上的重心是要求飞机在纵向水平上保持水平,通过定期称重来确定。横轴上的重心也可以同时确定,但这需要飞机在横向上达到水平状态,而这并非强制性要求,通常也不会这样做。若要测量垂直重心,必须将飞机的称重设备置于不同的、且确切已知的垂直位置上,然而,将飞机调整到这种特定的构型中涉及的物流过程极为复杂,以至于几乎无人实施。从操作的角度来看,了解横向和垂直重心的信息性大于实际应用,对飞机的日常运作并无直接影响。

在波音进行飞机的初始设计和认证分析时,我们确实会计算三个维度上的重心。然而,鉴于在飞机的实际运营中并不对横向和垂直重心进行测量或跟踪,任何可能受到这些重心变化影响的限制条件都会被转化为其他形式。如:对于横向重心,这通常体现为对飞机左右两侧重量差异的限制。实际上,飞机的真实重心并不恰好位于左/右0.0的位置,但相差不远,通过控制左右两侧的重量差异,我们可以确保飞机在实际运营中的重心保持在分析预测的范围内。

垂直重心一般不会成为设计限制的主要因素,因为在设计阶段,设计团队通常会考虑到特定飞机构型可能出现的垂直重心范围。由于这一范围已经覆盖了运营人可能为飞机设定的所有垂直重心位置,因此,运营人在实际操作中不会遇到设计阶段未曾考虑的垂直重心情况。

飞机在飞行过程中会围绕其三维重心进行旋转。这个重心的位置会随着飞机装载状态的变化而移动。因此,从飞行旋转的角度来看,这三个轴在飞机重心处交汇。然而,所有的重量和平衡计算都是相对于一个特定的刻度进行的,这个刻度的原点(x, y, z) = (0, 0, 0)通常位于机头前方(沿x轴),飞机中心线(沿y轴),以及大约在主舱地板以下200英寸(沿z轴)的位置。

问题二:

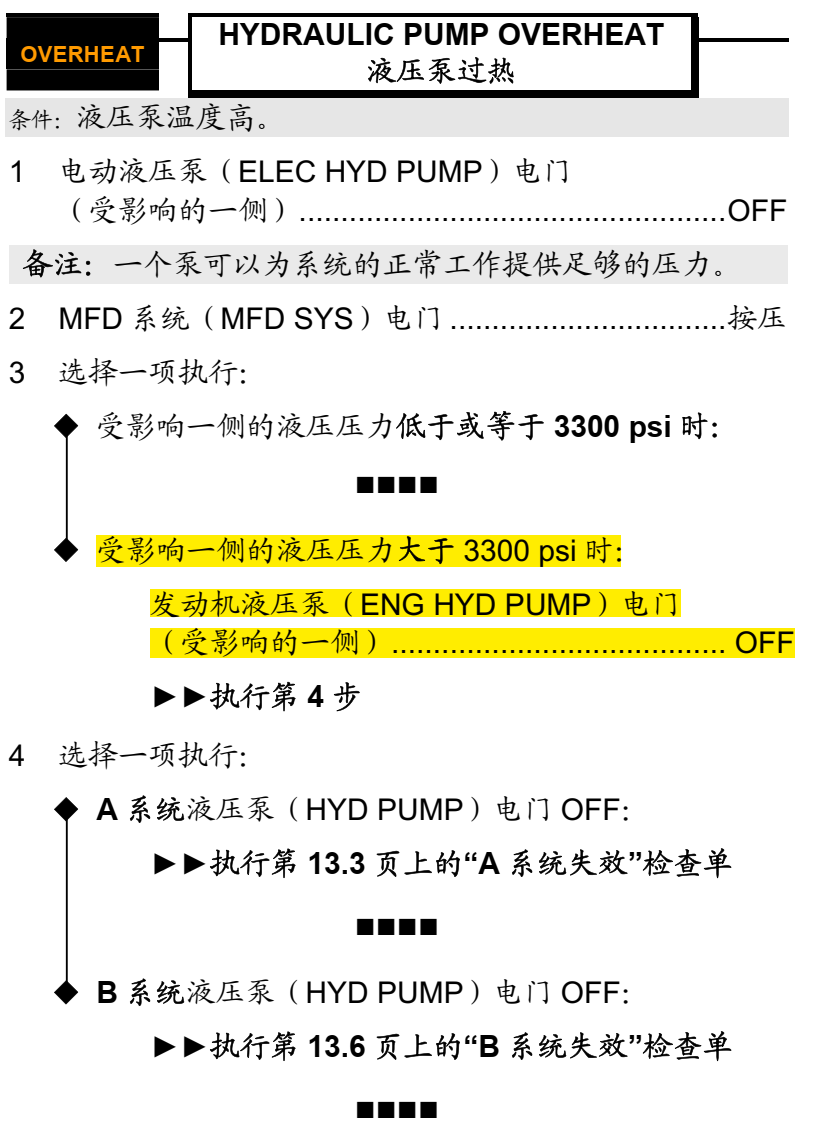

In the hydraulic pump overheat checklist, why we use 3300psi of hydraulic pressure to decide whether we need to put the ENG HYD PUMP switch off, and what is the reasoning behind this?

液压泵过热检查单中为什么液压泵过热要以压力3300PSI为界限判断?

提问人:盛磊

RESPONSE:

Hydraulic system thermal analyses for 737 MAX certification identified an engine driven pump failure mode that may result in surface temperatures in excess of 450F in flammable fluid leakage zones. The hydraulic pumps used in the 737 hydraulic systems are variable displacement, pressure compensated pumps. Internal failures of the pump displacement control mechanisms (such as a jammed compensator spool, or jammed stroking piston) may result in the pump becoming 'stuck' at any level of volumetric displacement between zero and full flow. If the pump becomes stuck producing more flow than required by the user systems, the hydraulic system pressure will rise until the hydraulic system pressure relief valve is activated. The relief valve prevents excessive pressures but heat is generated by the extra flow bleeding off in the return circuit. The degree to which the hydraulic system is heated depends on the sustained flow rate through the relief valve.

Surface temperatures of equipment in flammable fluid leakage zones must remain below 450F to support compliance with 14 CFR / CS 25.863 for 737 MAX certification. The HYDRAULIC PUMP OVERHEAT checklist mitigates the risk of exceeding the surface temperature limit in the in flammable fluid leakage zones by turning off the affected ENG HYD PUMP switch when the affected system hydraulic pressure is greater than 3300 psi.

If attachments are referred to and are not present, please access them by logging into the Boeing Communication System on MyBoeingFleet or contact your Boeing Field Service Representative.

Sarah Parsley, Flight Operations Support

Ryan Vas, Manager

Customer Support

The Boeing Company

BCA Operations Centers 24 Hour Contact Numbers

787: +1 (206) 544-7787

All Other Models: +1 (206) 544-7500

回复:

737 MAX 审定的液压系统热分析发现,发动机驱动泵故障模式可能导致易燃液体泄漏区域的表面温度超过450F。737液压系统中使用的液压泵是排量可变、压力补偿泵。泵排量控制机构的内部故障(如堵塞的补偿器阀芯,或堵塞的冲程活塞)可能导致泵在零和全流量之间的任何体积排量水平上“卡住”。如果泵卡住产生的流量超过用户系统所需的流量,液压系统压力将上升,直到液压系统释压活门工作。释压活门防止压力过大,但热量是由回路中多余的流量流出产生的。液压系统被加热的程度取决于通过释压活门的持续流量。

易燃液体泄漏区域的设备表面温度必须保持在 450F 以下,以支持符合 14 CFR / CS 25.863 的 737 MAX 审定。当受影响的系统液压压力大于 3300 psi 时,液 压泵过热检查单通过关闭受影响的发动机液压(ENG HYD)泵电门,降低了在可燃液体泄漏区域超过表面温度限制的风险。

评论 (0)